)—When a number of microorganisms is specified, it truly is the maximum number of colony-forming units (cfu) per cubic meter of air (or for every cubic foot of air) which is linked to a Cleanliness Class of controlled atmosphere dependant on the

AdvanceTEC cleanrooms are designed and created to meet exacting efficiency requirements and specs.

Pressure Differentials: Ensuring that cleanrooms retain proper favourable or destructive strain differentials to prevent contaminated air from entering important locations.

Staff are one of the most important sources of contamination in cleanrooms. Skin cells, hair, and respiratory droplets can introduce microbes and particles into a sterile environment. Appropriate gowning and habits protocols are necessary to retaining the cleanliness of pharmaceutical cleanrooms.

This guide will delve into the vital aspects of cleanroom sterilization, such as the most recent tools, regulatory compliance, and rising trends that may condition the industry in the coming several years.

Operational Qualification (OQ): Analytical calculation of equipment operational potential is completed while the piece of equipment is in Procedure.

Microbial Contaminants: Bacteria, fungi, as well as other microbes that may cause bacterial infections or spoil medicine. These are definitely particularly about for sterile products like injectables.

Adjustments have to be assessed by dependable managers, given that unauthorized adjustments in the layout for machines or personnel stations could bring about increase in the possible for contamination of your merchandise/container/closure method.

Microbiological checking of staff is also staying get more info integrated into instruction plans. Common screening of gloves and gowns employing Speak to plates or swabs offers quick comments over the effectiveness of aseptic approaches and helps reinforce very good methods.

This federal document only applies to airborne particulates within a controlled ecosystem and isn't meant to characterize the viable or nonviable character with the particles.

Environmental microbial checking and Evaluation of knowledge by capable staff will permit the position of Regulate to generally be maintained in clean rooms and other controlled environments.

Normal environmental monitoring ensures that the cleanroom continues to be compliant with regulatory standards and read more will help manufacturers recognize probable contamination threats just before they have an effect on merchandise excellent.

by preserving contaminants from injections, drops, along with other sterile compounding preparations; Whilst, USP 800 rules emphasize worker basic safety

Sampling Websites —Documented geographical location, in just a controlled natural environment, in which sampling for microbiological analysis is taken. Generally, sampling web pages are picked due to their opportunity for merchandise/container/closure contacts.

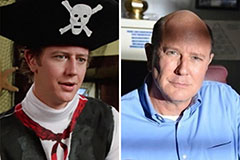

Rider Strong Then & Now!

Rider Strong Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!